A COG production line is not solely about the bonding machine itself. It encompasses the steps immediately preceding and following the actual chip-to-glass attachment. These typically include:

- Glass Loading and Pre-treatment: Panels are loaded from storage or the previous cleaning stage. Sometimes a localized pre-treatment (like plasma cleaning) might occur on the bonding area to enhance adhesion before the ACF is applied.

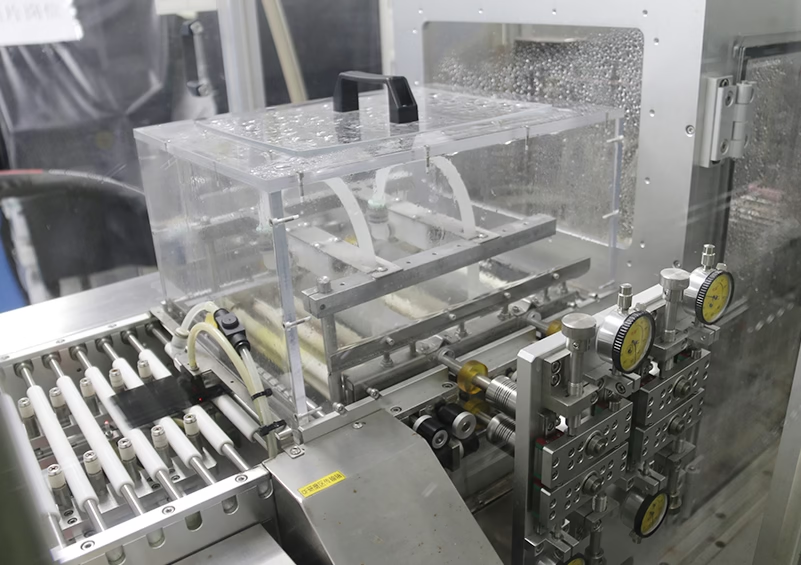

- ACF Laminating: The Anisotropic Conductive Film (ACF), critical for COG bonding, needs to be precisely applied to the bonding area on the glass substrate before the IC is placed. Automated laminating equipment ensures the ACF strip is accurately positioned and adhered.

- IC Feeding and Picking: Driver ICs are automatically fed from trays or tapes and picked by a robotic arm or vacuum head, often after undergoing automated visual inspection for defects.

- COG Bonding: This is the core step performed by the COG bonding machine, as detailed in the previous article, where the IC is aligned and bonded to the glass via the ACF under controlled heat and pressure.

- ACF Curing (Post-Cure): While bonding applies initial heat and pressure to create electrical contact and partially cure the ACF, a full cure is often required to achieve maximum mechanical strength and long-term reliability of the bond. This might happen in a separate oven or heating station within the line.

- Initial Visual and Electrical Inspection: Immediately after bonding and curing, automated optical inspection (AOI) systems verify the alignment and physical integrity of the bonded ICs. Some lines may also incorporate preliminary electrical testing to check for basic conductivity or shorts.

- Unloading: The processed panels are automatically unloaded and prepared for transfer to the next major assembly stage, such as FPC bonding or backlighting assembly.

The Significance of Line Integration and Automation

The power of a COG production line lies in its integration and automation. Each station is linked by automated material handling systems – conveyors, robotic arms, or transfer stages – that move panels smoothly and precisely from one process to the next without manual intervention. This continuous flow is vital for several reasons:

- Speed and Throughput: A well-integrated line maximizes efficiency by minimizing idle time between stations and allowing multiple panels to be processed simultaneously at different stages. This is essential for high-volume manufacturing.

- Consistency and Repeatability: Automation ensures that process parameters (like temperature, pressure, time, and alignment) are consistently applied to every single panel, significantly reducing variability and improving overall yield.

- Cleanliness and Damage Prevention: Automated handling minimizes human contact with the delicate panels and ICs, reducing the risk of contamination, scratches, or electrostatic discharge (ESD) damage, all of which can lead to defects.

- Traceability: Automated lines often incorporate systems for tracking each panel through the process, enabling better quality control and analysis of potential issues.

Quality Control Within the Line

Quality is monitored rigorously throughout the COG line. Automated vision systems are critical for verifying ACF placement, IC orientation, and, most importantly, the alignment and physical condition of the bonded ICs. These systems can detect minute misalignments or defects that would be impossible to catch manually at production speeds. Any panels failing these checks are automatically flagged or removed from the line.

Connecting to the Next Steps

The output of the COG production line is a glass panel with the driver ICs securely attached and ready to communicate electrical signals. This panel, now often referred to as a Cell or Panel Assembly, is the core component that will receive further attachments like flexible printed circuits (FPCs) and eventually be integrated with backlighting, bezels, and other components to form the complete LCD module. The quality and reliability established in the COG line are foundational for the success of all subsequent assembly steps.

In conclusion, the COG Production Line is a highly sophisticated, integrated system that transforms cleaned glass substrates into partially assembled panels with functional driver electronics. Its reliance on automation, precision, and integrated quality control is fundamental to achieving the speed, efficiency, and high yield required for modern LCD manufacturing, directly contributing to the performance and cost-effectiveness of displays we use daily.